VEEMS Hull and Propeller

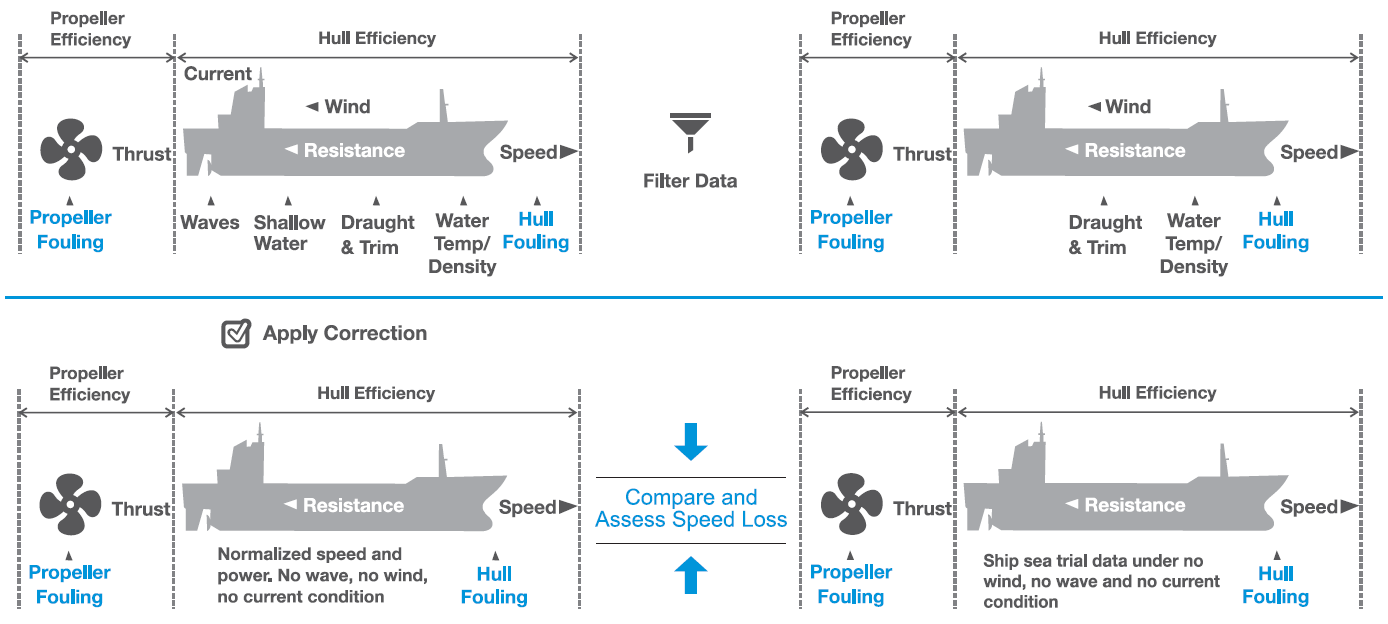

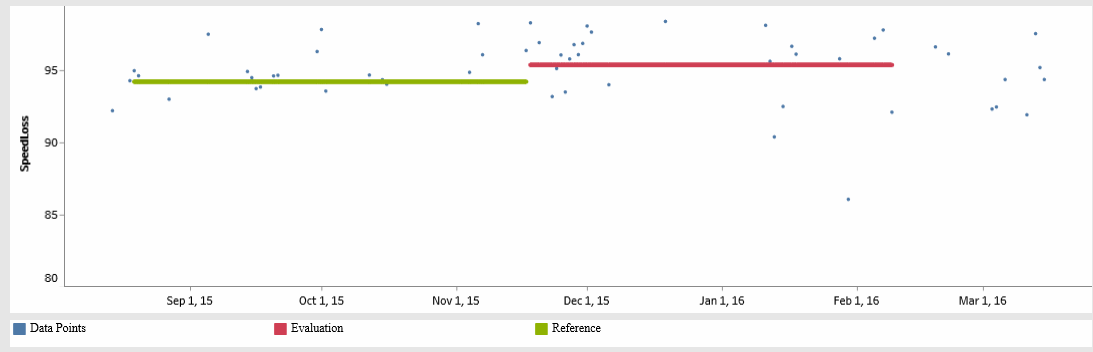

By providing performance indicators in accordance with ISO 19030 international standard, VEEMS Hull and propeller module offers fully transparent assessment of Dry docking performance, In service performance, Maintenance trigger and effect of maintenance on hull and propeller for in service ships. ISO 19030 being an international standard is expected to provide the much needed transparency for buyers and sellers of technologies and services intended to improve hull and propeller performance and thereby facilitating performance based contracts between the concerned parties. With automated data processing combined with on-board ICT platform, VEEMs can be at the forefront of facilitating this purpose and should be acceptable to multiple parties.

Challenges in hull and propeller maintenance:

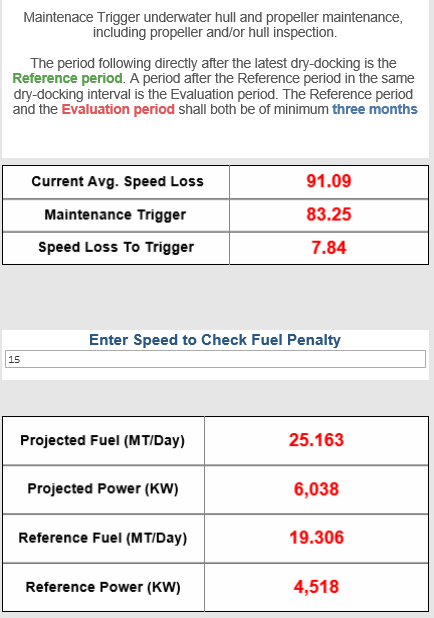

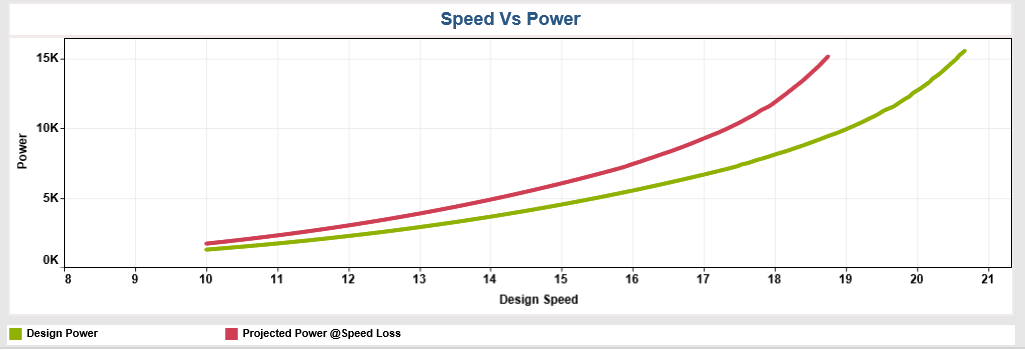

In service maintenance: Usually cleaning of hull and polishing of propeller is carried out periodically to maintain the surface roughness. Cleaning/polishing a propeller can reduce propulsion fuel consumption as much as 3% whereas cleaning a light slime from hull can reduce fuel consumption up to 7 to 9%.

Benefits:

- There is no additional work load for ship staff. It actually reduces regular reporting workload by filling up reports automatically where ship staff need to enter data that cannot be captured through sensors , verify and submit it.

- All four performance indicators from ISO 19030 are automatically calculated and shown in easy to understand interface.

- Quantification of fuel penalty due to hull & propeller degradation helps in the decision making process for propeller polishing, Hull cleaning

- Value added features are available without additional cost such as Fleet performance analysis, emission reporting such as EU MRV, IMO fuel reporting etc.

Technical highlights:

Knowing when to undertake such cleaning, quantifying the improvement are critical information that you need for successful management.

Selection of paint/PID’s: A suitable hull coating technology can reduce fuel consumption between 1 – 5%. There are also PID’s (propulsion improving devices) which can also reduce fuel consumption to similar level. However, lack of transparency oftentimes comes in the way in uptake of such suitable technology.

VEEMS – Solution:

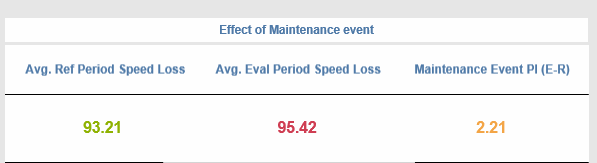

Maintenance Trigger and Maintenance effect: A trigger value can be set in VEEMS which will automatically alert you when the hull &propeller performance is dropped to the trigger level. This will help you in monitoring multiple ships with ease and provide decision support for planning any maintenance activity. The improvement after the maintenance is quantified and provides useful information on the effectiveness of the maintenance event.

Benefits:

- There is no additional work load for ship staff. It actually reduces regular reporting workload by filling up reports automatically where ship staff need to enter data that cannot be captured through sensors , verify and submit it.

- All four performance indicators from ISO 19030 are automatically calculated and shown in easy to understand interface.

- Quantification of fuel penalty due to hull & propeller degradation helps in the decision making process for propeller polishing, Hull cleaning

- Value added features are available without additional cost such as Fleet performance analysis, emission reporting such as EU MRV, IMO fuel reporting etc.

Technical highlights:

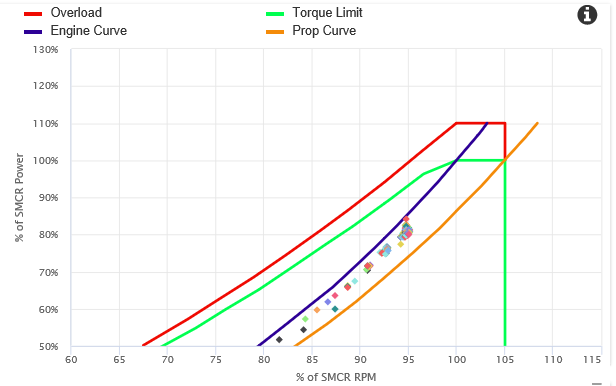

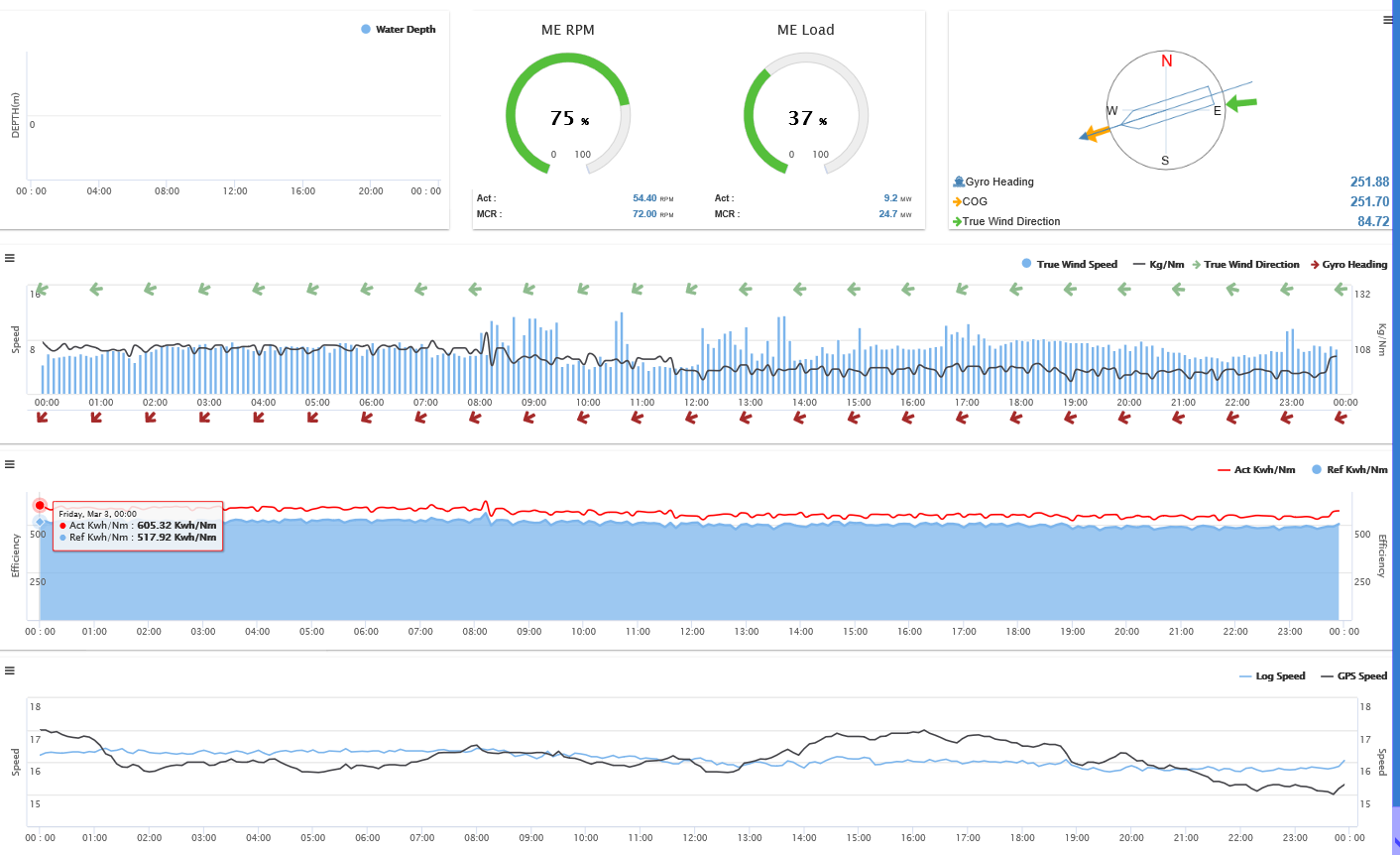

Existing on-board sensors that are integrated with the system:

Bridge: DGPS, Speed log, Echo sounder, Rudder angle indicator, Gyro and Anemometer, Draft gauges.

Engine room: Shaft power meter and rpm, Main Engine flowmeter (optional),

Hardware provided:

Dedicated high speed server

Customized data acquisition unit